Manufacturing is no walk in the park. Today’s marketing climate seems to be paced more at a constant sprint, from the product design and development, to manufacturing and retail. Having to also manage the health and performance of your external assets can also have you under pressure.

This is why we provide our Peace of Mind service for a stress-free manufacturing experience. Rotadyne provides you with a moments rest, as you leave the moulding maintenance to us.

In the words of Mahatma Gandhi, peace is its own reward. But if that’s not enough, our Peace of Mind service is also financially beneficial! Rotational moulding tools are known to be significantly cheaper than tools used in other plastic moulding processes. However, what is often overlooked are the costs of maintaining and repairing those moulds, as well as costs attached to the preventative measures that are taken in storage, transport and usage. These are important steps which directly impact the tooling’s lifespan and the quality of the produced parts.

Keeping all stages of production in-house with Rotadyne will save you time, costs and stress associated with the shipping and handling involved in outsourcing these services. It also allows tools to be used for the full capacity of their service life, meaning less costs on replacements and ensures high quality production results.

If you order your mould through us, we will provide complimentary storage, cleaning, repair, and general maintenance for all tooling here on site. This allows you to experience manufacturing with less pressure, and more productivity, using a preventative mould maintenance approach which considers the care and condition of the tool during all stages including storage.

WHAT’S INCLUDED?

- MOULD OPTIMISATION: Our in-house design services will ensure your part and mould are optimal for manufacturing. Once a design is approved, we order in your tool.

- STORAGE: Once arrived, your tools are each palletised and safely stored in a designated shelf space.

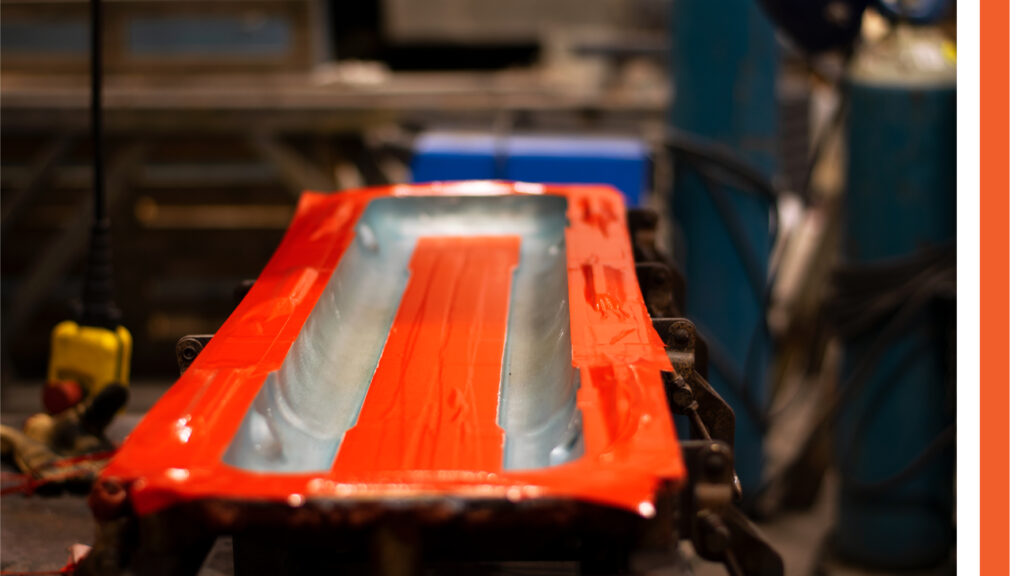

- ASSESS, REPAIR, MAINTAIN: Your mould will undergo regular quality assessments to find and fix any scratches or scars that accumulate during production which would directly impact the quality of the parts beings produced. Additionally, we regularly apply treatments and repairs which preserve the moulds integrity and upholds a quality finish.

Some say the creation and maintenance of moulding casts is an art, one which should be handled exclusively by specialists who have sufficient knowledge, precision and passion in rotational moulding. It is certainly true that the quality of the tooling can severely influence the products final quality, so it is important to source and service your moulds through someone you trust. Walk in the direction where peace is found, and experience manufacturing excellence as your mould is pampered with the full five-star service.

Peace is not the highest goal in life; it is a fundamental requirement. At Rotadyne, we have your moulds under control, so you can let go.