We’ve wrapped up 2023 and are officially in the new year! We want to extend our deepest thanks to our incredible team, devoted clients, and valued partners. It’s the collaborative spirit that has kept us going and we couldn’t be more grateful for the dedication and hard work that each of you has brought to the rotational table.

Together, we’ve shaped a year filled with achievements, laughter, and innovation. Now, we’re gearing up for even more twists, turns, and exciting developments. But first, we’d like to reflect on the 8 major milestones of the last year.

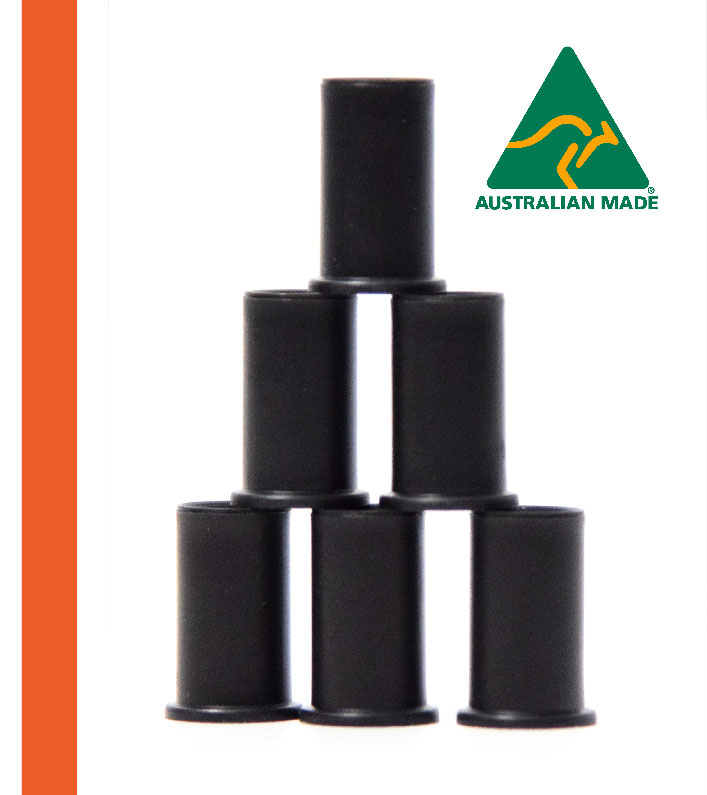

1. Australian Made License Extended to Pool Fittings Range

1. Australian Made License Extended to Pool Fittings Range

Our Pool Heating Fittings have officially earned their Aussie stripes.

Alongside our Marine Range, our Pool Heating range is now officially Australian made Certified meaning the materials and manufacturing are all locally produced. This is important for us to show our dedication to supporting Australian economies and communities, and to emphasize the level of quality and care we take into our products.

Cue the kangaroos hopping with joy, as we add another Golden Roo to the Rotadyne records!

2. New Branch Initiated: Engineered Systems

2. New Branch Initiated: Engineered Systems

A major change has occurred over the last year: we’ve established a new department, which introduces an engineering edge to our design and manufacturing services. Our Engineered Systems department provides completed systems for water, chemical and wastewater applications.

Our specially engineered system packages work to achieve superior sewerage solutions, and are designed for optimization with municipal areas.

We soon hope to expand upon this department with water treatment systems, as well as chemical dosing systems.

3. EXTRA LARGE Launch for Alemlube!

3. EXTRA LARGE Launch for Alemlube!

One of our favourite things about end of year reviews, is looking back on our client wins! One of our longest running clients, Alemlube, have released new variants this year of their extremely popular Disel Transport Tanks, this time with tank reaching a whopping capacity for up to 1200L.

Our designer James Torres worked on this project in its design, trialing and testing. It features a common lockable lid, accessible external nozzle storage options for all needed components, and be structurally designed for maximum strength.

4. ARMA 2023 Conference: Igor Silva Presents on Sustainability

Our very own designer and Product Development Manager, Igor Silva, presented at this year’s ARMA Rotomoulding Conference in New Zealand. He took the stage to discuss sustainability data, trends, and practices in industrial design and manufacturing.

After teaching Sustainable Design at Western Sydney University for two years, and working on projects here at Rotadyne with a strong environmental focus, Igor has the know-how and expertise to lead the discussions for both students and industry giants alike on the strengths, weaknesses, threats and opportunities found in designing for a circular economy.

We are excited to see where his focus and research could take Rotadyne next as he continues on in 2024 to begin a PHD in recyclable materials!

5. Zero Pellet Left Behind: Rotadyne Commences Operation Clean Sweep ️

5. Zero Pellet Left Behind: Rotadyne Commences Operation Clean Sweep ️

We’ve made the commitment, we’ve signed the pledge. Operation Clean Sweep is officially all systems go!

Reduction of pellet loss in manufacturing companies can be difficult: resins and powders are fickle and difficult to maintain complete control over. No business can guarantee that every pellet stays perfectly put- but it’s certainly a lot worse if you’re not even trying!

This pledge is a promise to our planet, our community, and ourselves that we will take the steps necessary to achieve zero pellet loss in our manufacturing operations. This means in both resin handling and in housekeeping efforts, taking care to keep them in our moulds, and out of the environment and waterways.

When it comes to environmental stewardship, we’re not just molding products; we’re molding a sustainable future. Here’s to turning the tide!

6. Stand Out Staff: Ethan’s ‘Fitting’ In!

6. Stand Out Staff: Ethan’s ‘Fitting’ In!

We love to shine a spotlight on the successes of our standout staff. One face many of our clients may recognise is our long-time Leading Hand and Machine Operator, Ethan.

This year, he has begun a new mission both in his working career as well as in our company’s efficiency: a Fitter’s apprenticeship! With one year down and another three to go, we hope that this brings the future benefits of reduced mould downtimes, customisation capacities enhanced quality control and investment protection.

As we gear up for more twists and turns in the world of rotational moulding, having Ethan as our in-house certified Fitter is like having a superhero for our moulds – ensuring they stay in tip-top shape and ready for action.

7. Ryno’s Gone Down Under

Another new client reached our factory floors this year. Australian company for specialised furnishing, Crown Furniture, are distributors of the Ryno Chair here in Australia, working with the product’s owner: a UK based, mindful furniture design company called Pineapple. Now, this chair is being manufactured here in Australia, here at the Rotadyne Factory.

This chair is designed for challenging environments such as Mental Health facilities with the intention of minimising the risk of harm from the common weaponization of furnishings. The unique and iconic design are tailored for increased robustness and stabilisation for added functionality and safety precautions.

Crown approached Rotadyne with an enquiry to produce the Ryno Dining chairs in order to optimize logistics and minimize costs. As Ryno brings its mission to fortify mental health spaces to the heart of Australia, we’re proud to join forces in manufacturing seats that stand strong against impact!

5. 50 Years of Rotadyne

5. 50 Years of Rotadyne

Happy Birthday to us!

50 years and counting – we’re not just in the business of plastic, we’re in the business of timeless innovation. When you’ve been around as long as we have, you learn to mould success, and outlast trends. Our foundational values of quality, expertise, and turn-key solutions have not only kept our machines running, but have also cemented our place in rotomoulding history.

We have adapted to new challenges, expanded our vision, and helped countless clients take their inspired ideas into industry-changing realities. We’re proud of having half a century of bending, moulding, and shaping the industry under our toolbelts.

Here’s to 50 years of molding the future, one plastic masterpiece at a time! We’ve got some exciting plans in the pipeline from ground breaking technologies to new product launches: there’s a whirlwind of innovation coming your way.

Want to be notified of our future milestones and projects? Are you keen on being the first in the know for valuable industry insights?

Well Rotadyne’s spreading the news!

Sign up to have our upcoming innovative and inspiring content delivered straight to your inbox in our 2024 RotaNews Newsletter.

Or, you can connect with us on our social media platforms for the latest updates. Feel free to reach out with any inquiries or feedback!