Packaged Pumping Station

SUPERIOR SEWAGE SOLUTIONS

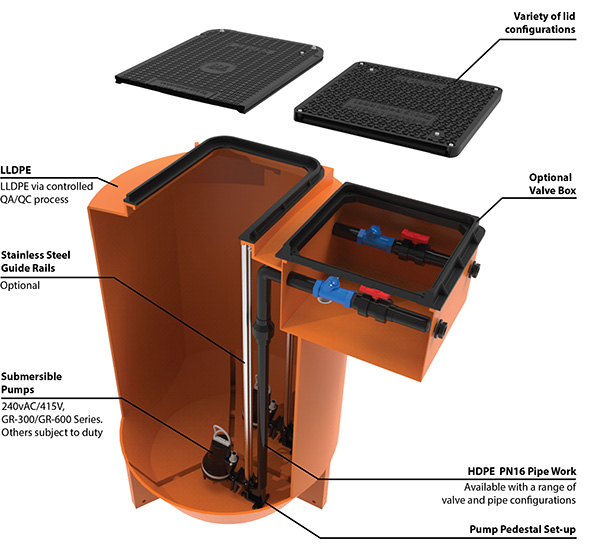

With a range of Polyethylene tanks up to 10,000L and up to 5m in depth, our Packaged Pumping System can service a large catchment area. The system can be customized to add additional storage as required via a range of Polyethylene storage logs and other ancillary setups such as external valve boxes.

Ideally suited to the needs of privately owned and operated infrastructure, this cost-effective solution is with a control panel which can be configured for local alarm setup or 4G remote alarms. The station is ideally suited to small to medium multi-level living, gated communities such as retirement villages and small light industrial parks.

Key Advantages

Durability

- Corrosion Free (LLDPE) collection chamber

- Compatible with acid sulphate soils

- Stainless steel guide rails and chain hoist

Credibility

- Australian owned manufacturing: 50 years experience

- Supporting buoyancy calcs and anchorage guidelines for site installation purposes

- Accreditations & Relevant Standards

Customisation

- Sized for your duty and control needs

- Class rate lids

- Configurable tank setups (max. depth 5m)

- Local and remote SMS alarms

Practicality

- Compact ‘Plug & Play’ control cabinet IP65

- Full automation control (inclusive of level control instrumentation)

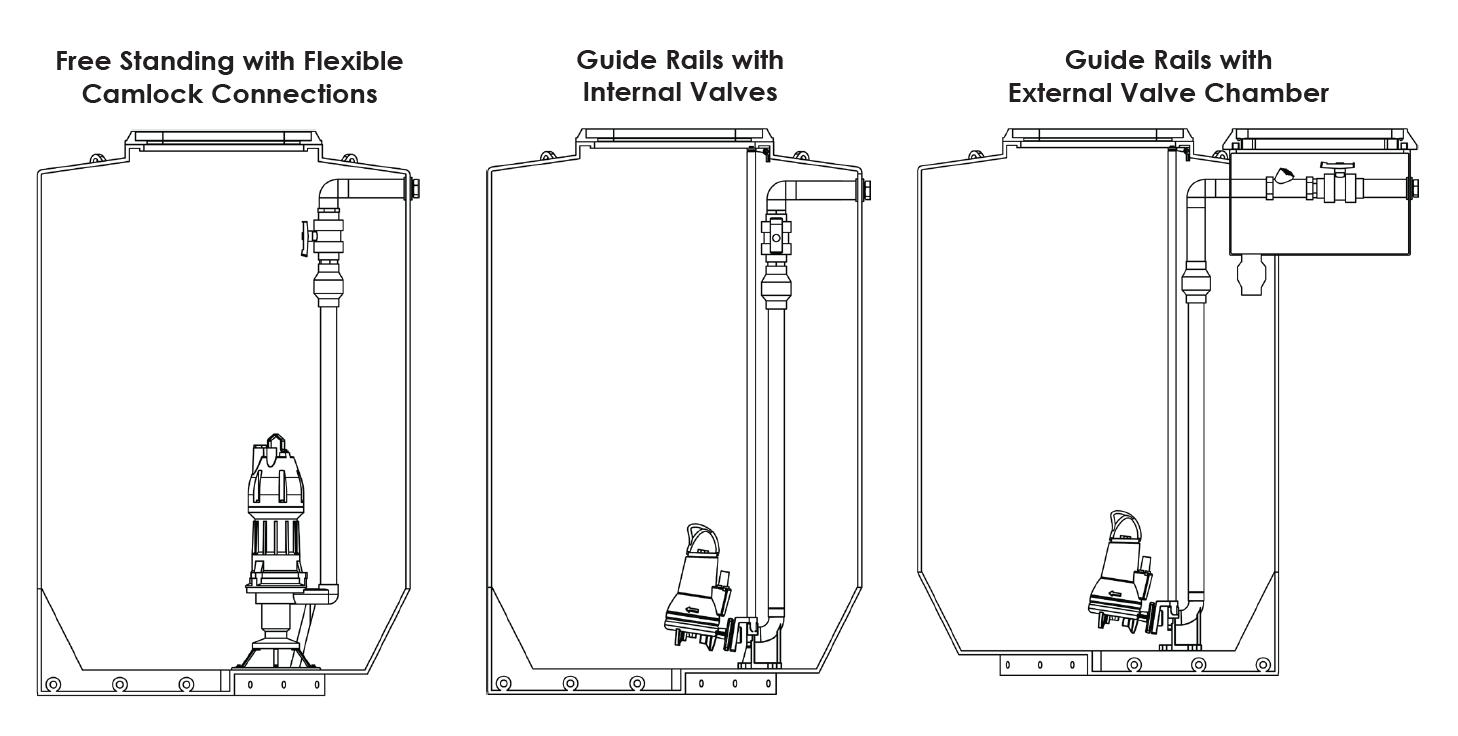

- Internal or external isolation and check valve setup

- Expandable extra emergency storage (via storage logs)

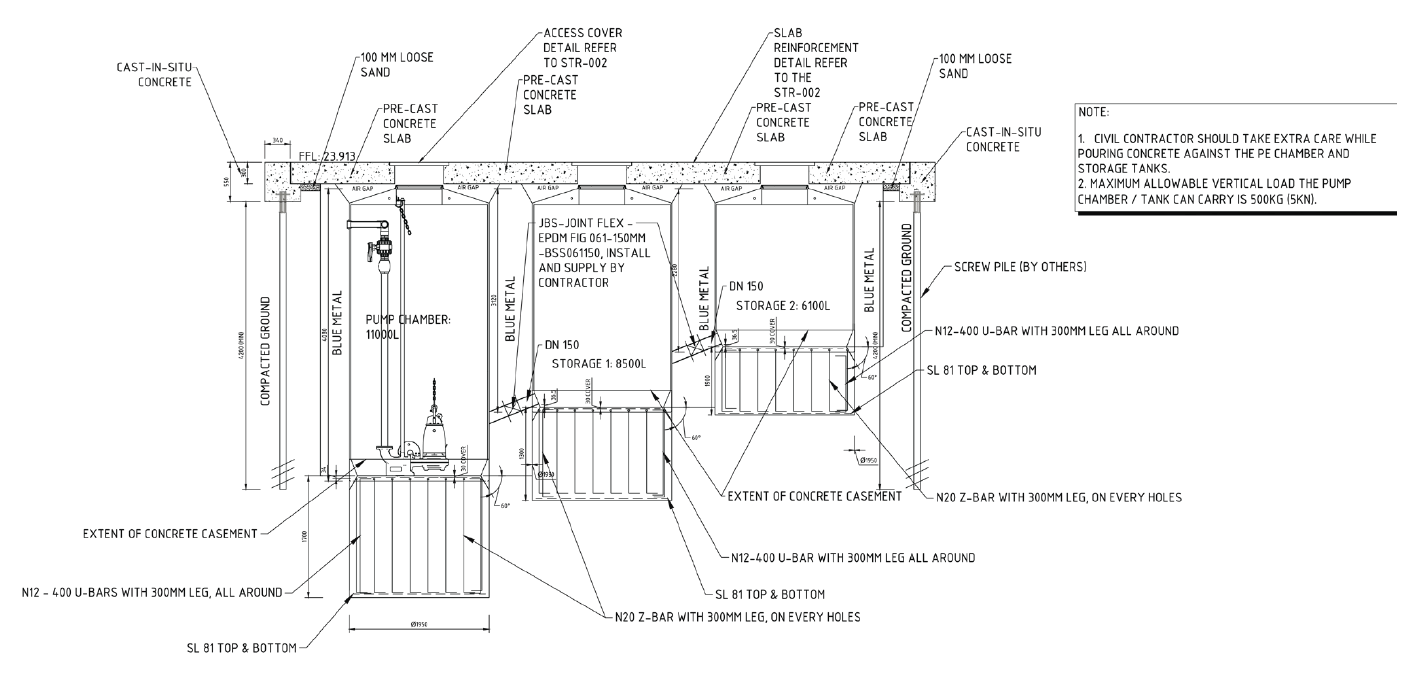

Custom Pump Station Set-Up & Civil Design Support

We know that not all sites are easy to install your pumping system within. Your site may be in water charged grounds, unstable soil or your pumping station may need to contend with lateral loads from heavy traffic or even have to contend with service vehicles driving over the pumping station.

For all these sort of difficult scenarios, we can support you with an overall functional site specific design to support civil construction, inclusive of structural slab designs as necessary, to limit load transfer to the pumping chamber.

Pump Controller Set Up

- Powder Coated weatherproof steel cabinet with dial up overload protection, 4G

- Touch pad control and LED indicator lights

- Suitable for use up to 10amp

- Toggling pump operation for duty/standby control operation

- High level alarm

- Alarms functions with time delay

- Auto and manual bypass operation

Level Floats Module and Pressure Switch

Used to start and stop pump transmit high levels within the pumping chamber and

It’s robust, fail safe, design ensures longevity. Settable Pressure Switch incorporation for safety.

Optional submersive transmitter:

Utilised for controlling the operating volumes remotely* delivering high levels of accuracy.

- Available as a standard setup with a caged or extended face diaphragm.

- 24V DC, 4-20mA Output & SS Housing

*Subject to use of remote SCADA monitoring & pump controller extension upgrade.

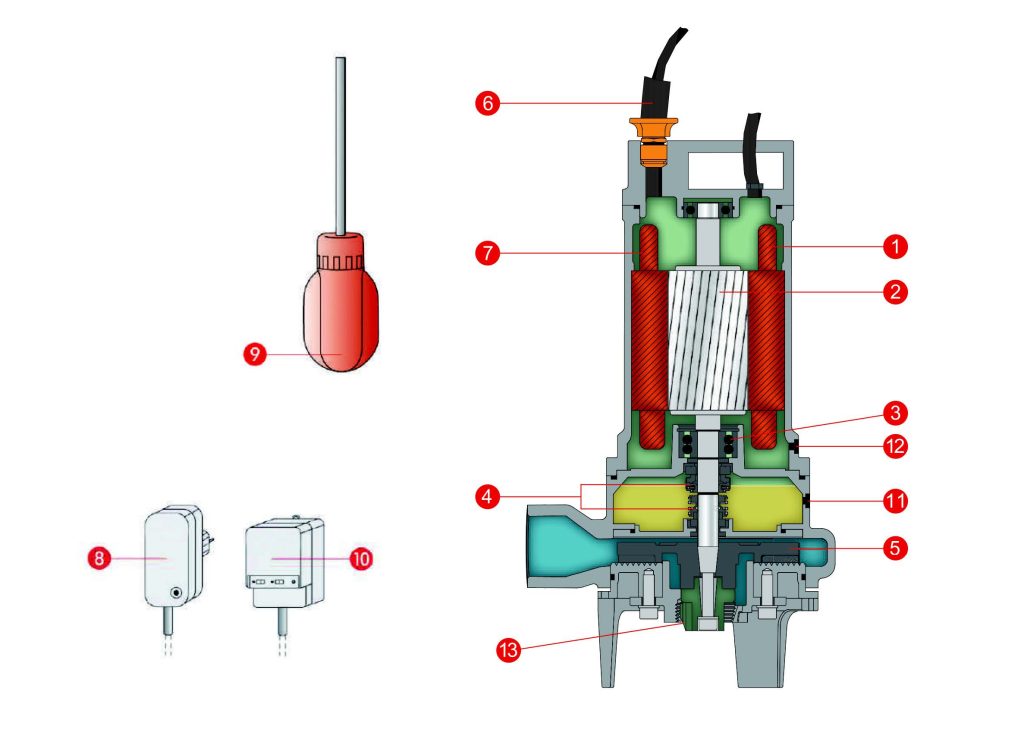

Technical Features

- Fully submersible pressure tight electric motor

- lnsulation class H. Protection degree IP 68

- Speed: 2850 rpm. Voltage: single-phase 1x230V-50 Hz Three-phase 3×380/415V-50 Hz

- Different voltage and frequency on request. ATEX certification in progress

- Shaft in stainless steel AISI 420

- Bearings over-dimensioned long-life

- Double mechanical seal in oil chamber

- Water side: silicon carbide/silicon carbide

- Motor side: graphite/alumina

- Open lmpeller with cutting device

- Cable H07RNF

- Thermal protection embedded in winding

- Plug with capacitor

- Float switch regulator

- AET-AEM electrical gear for three-phase and single-phase execution

- Oil inspection plug

- Hole for the motor watertightness control

- Cutting device

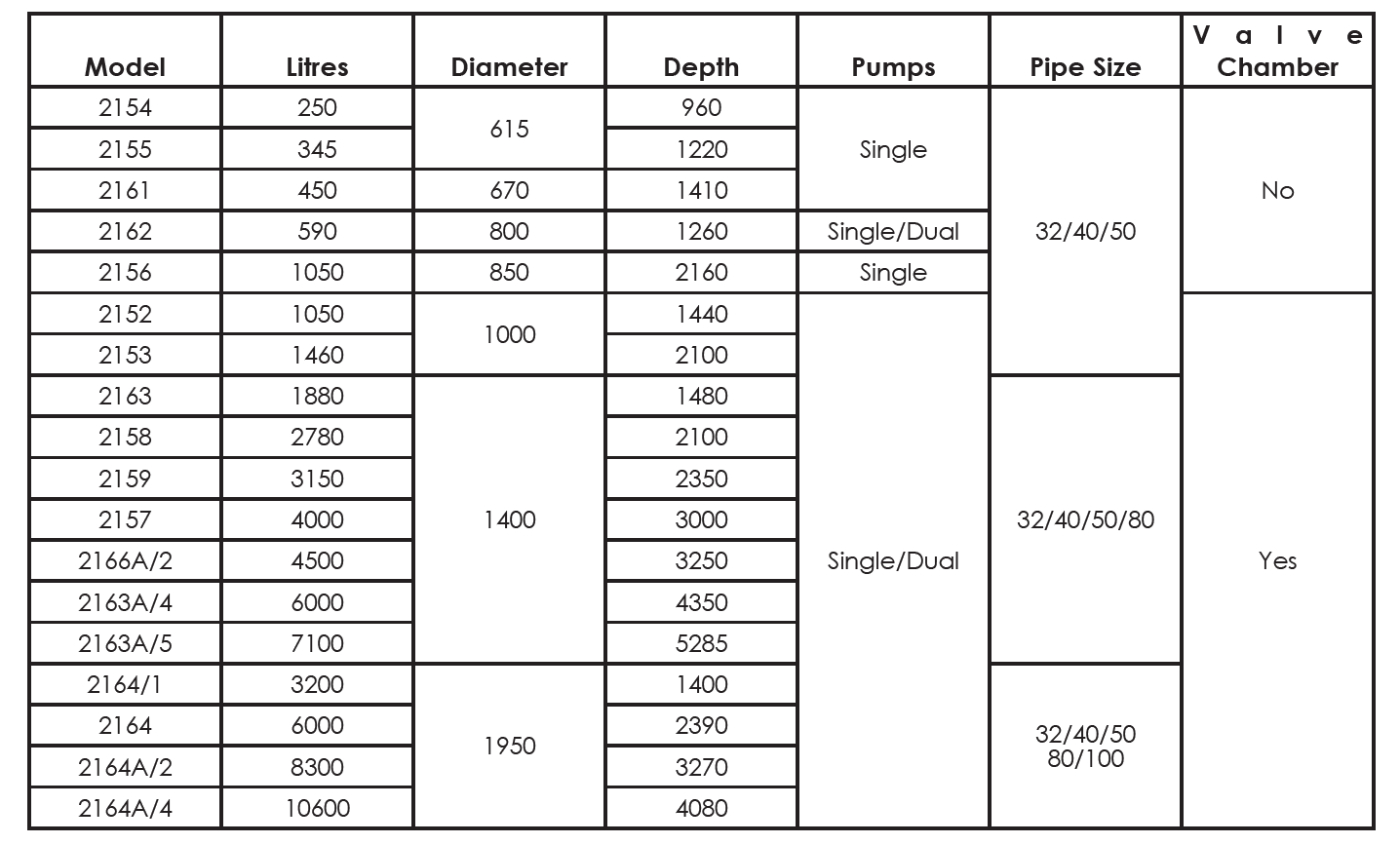

Standard Sizes & Configurations

LIDS

COMPOSITE WEATHER HATCHES

- Available as a 600 Diameter, 600 x 600 square or a 600×900 rectangle

- Lockable and “O” ring sealed to prevent water ingress from weather events.

- Supplied with stainless steel lock spanner and lifting handle.

- Rated to 510kg in accordance with AS1546.

- Flat layout avoids tripping hazards.

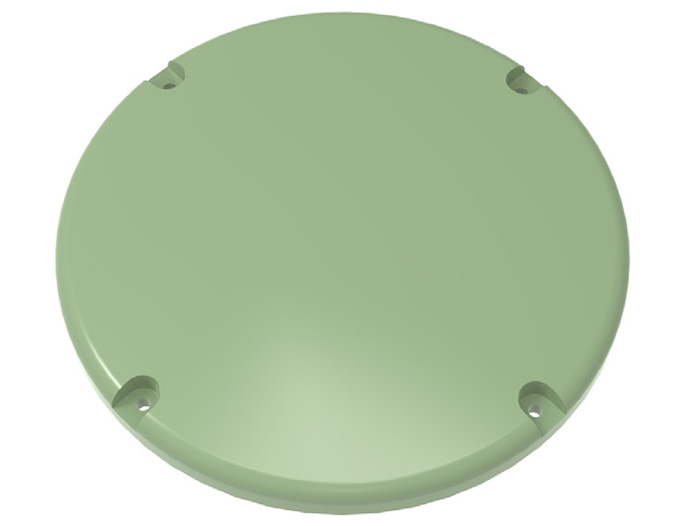

DOME PE HATCH

- 600 diameter unfilled polyethylene “garden style”.

- Non – trafficable, rubber strip sealed.

- Load rated to 110-300kg.

- Typically suitable and used for installations with the portion of tank protruding above finish surface level.

CUSTOMISABLE ACCESS

- We are also able to supply Iron hatches and covers with integrated safety grates for jobs where these are requirements.

Station Sizes & Configurations

Fit Out Options

- LLDPE tank/ LLDPE External valve box, complete with drainage check Valve

- Pump specification subject to duty and individual site-specific needs

- Duty/Standby Configuration of pumps within single pumping stage, subject to Duty

- Pressure rated PE/PVC Pressure Pipe/ Flexible Hose setup with Stainless Kamlocks

- Check and Isolation valving, Cast Iron 2 Paint Epoxy Coated/ PVC – subject to requirements: typical sizes subject to pump sizing – 50mm to 80mm” – larger sizes on application

- Stainless steel guide rails and chain

- Stainless Steel Discharge Pedestal and support base plates – subject to pump size.

- Stainless Steel eye bolts

- Level float control setup (Low/Start/Stop/High), complete with counterweight

- Typical Items Provided loose for setup on site by contractor/plumber

- 2 x 100mm/150mm EPDM rubber seals for gravity intake

- 2 x 50mm Stainless steel Electrical conduit penetrations

- 1 x suitably load rated and surround, subject to loading requirements

- Pumps

APPLICATIONS

Multi Level Living

Gated Communities