Rotadyne Water Technologies

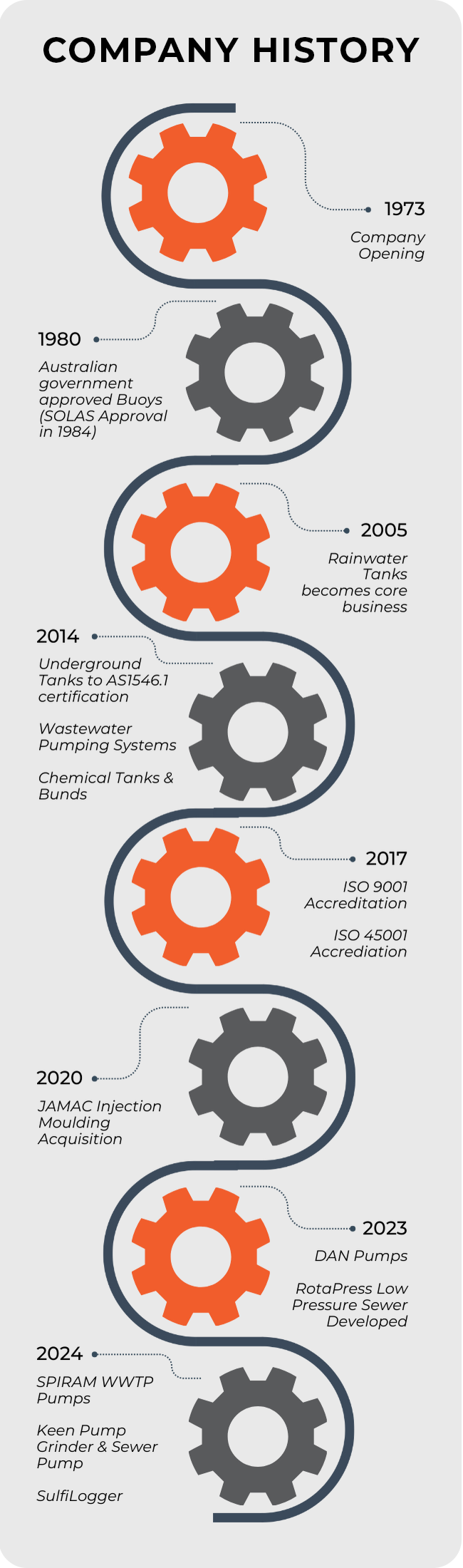

Rotadyne has been servicing the Water, Wastewater and Chemical sectors with fluid handling solutions since 1973.

We take great pride in continuing to be a Family-Owned Australian Manufacturer, where we employ and support over 30 families in our local community. From humble beginnings as a poly tank manufacturer, we now have evolved to a fully integrated systems provider servicing a diverse range of clients & applications.

When you work with Rotadyne, you support Australian Made & Owned, and you support local jobs and people.

Project Experience: Water & Waste

- Greenfield Developments

- Septic Tank Upgrades

- Remote Communities

- Shopping Centres

- Food Processing

- Wastewater Treatment Applications

- Contractor Accreditations

- Chemical Handling

ENGINEERING SERVICES

- Long sectional drawings

- Civil/structural design

- Mechanical & Electrical design

- P & ID development and functional description development

- Safety in Design/HAZOP’s

- Systems network design: Low Pressure Sewer/Vacuum Sewer/Gravity

- Master catchment planning

- Contractor accreditation and training

- Commission engineering and ITP’s

- Corrosion engineering

PRODUCTION CAPABILITIES

- 7 Rotational Moulding Machines

- Prototyping and small-scale additive manufacturing

- Mould Fabrication and Repair

- Product Development and R&D

- Extensive Storage Facilities & Warehousing

- Contract Manufacturing

- Custom Moulding/Fabrication

- Mould repair/build

OUR PEOPLE: OUR ENGINE

- Over a century of combined experience in our staff

- Design and Drafting

- Product Development

- System Engineering: Water, Waste, & Chemical applications

Key Advantages

Durability

- Corrosion Free (LLDPE) collection chamber

- Compatible with acid sulphate soils

- Stainless steel guide rails and chain hoist

Credibility

- Australian owned manufacturing: 50 years experience

- Supporting buoyancy calcs and anchorage guidelines for site installation purposes

- Accreditations & Relevant Standards

Customisation

- Sized for your duty and control needs

- Class rate lids

- Configurable tank setups (max. depth 5m)

- Local and remote SMS alarms

Practicality

- Compact ‘Plug & Play’ control cabinet IP65

- Full automation control (inclusive of level control instrumentation)

- Internal or external isolation and check valve setup

- Expandable extra emergency storage (via storage logs)