Rotadyne Water Technologies

LIQUID PHASE H₂S LOGGING

THE H₂S NUISANCE AT THE WASTEWATER TREATMENT PLANT & SEWER NETWORK

Hydrogen Sulphide (H₂S) emits a Rotten-Egg odour that can affect quality of life for nearby residents and staff. It is also a worker health and safety risk, paralysing the olfactory nerve above concentrations of 150ppm, leading to lethal consequences at concentrations above 500 ppm.

Furthermore, H₂S is corrosive, reducing the lifespan of valuable plant and retic network assets and can inhibit wastewater treatment processes also creating issues in biogas production.

what is H₂S costing the wastewater sector?

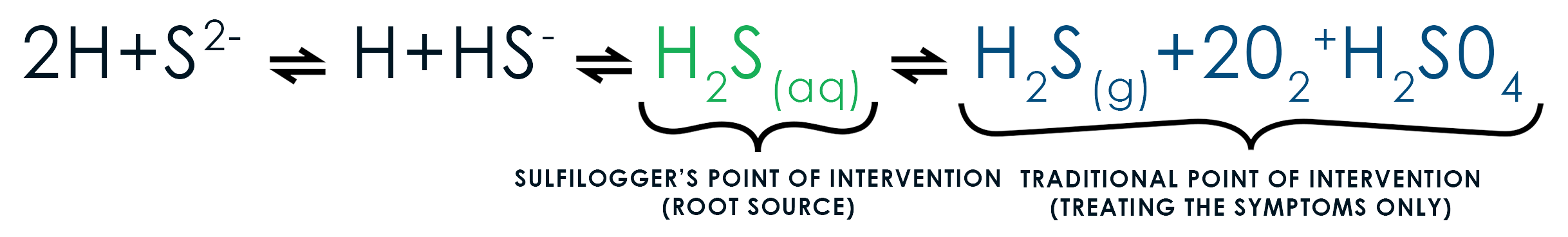

The wastewater industry is currently strictly dealing with H₂S related problems in the gas phase, after it has degassed out of liquid phase, resulting in odours and corrosion.

RISK & COST

- The very serious and real OH&S risk to life

- Reduced Asset life, due to corrosion

- Sewer Corrosion

- Odour – EPA compliance

- $950 million+ cost/year in Australia

- Inaccurate tracing of H₂S at its root source with only gas phase detection

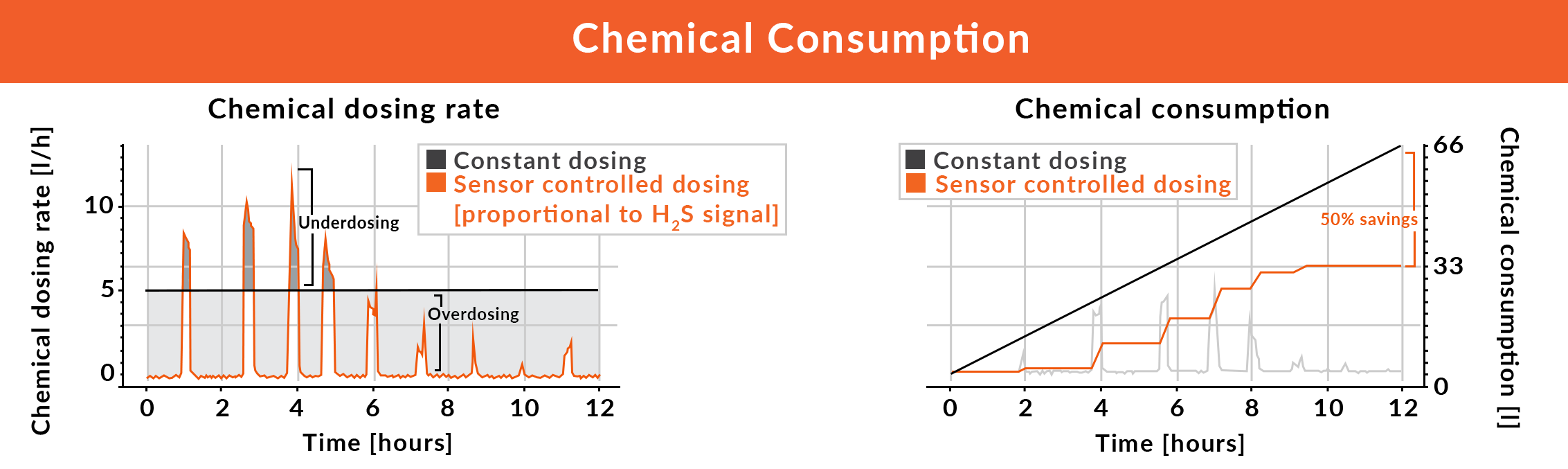

- Underdosing/overdosing of chemicals

LIMITATIONS OF DEALING WITH ISSUES IN THE GAS PHASE

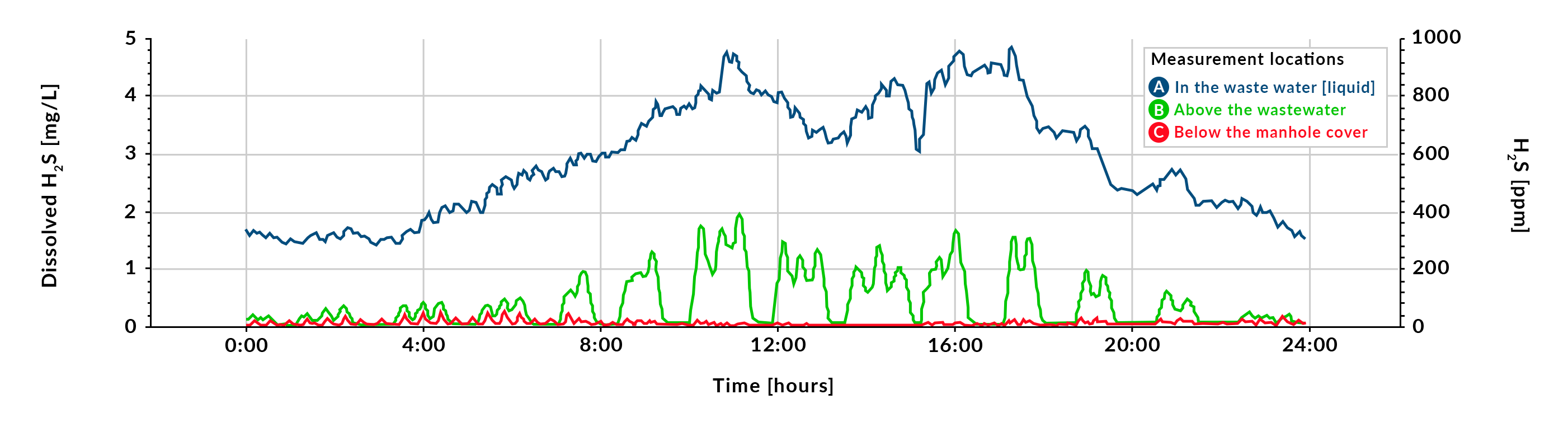

Gas-phase measurements are impacted by many variables, causing inconsistencies, and all measurements are impacted by the pronounced concentration gradient from liquid to gas phase.

- Problems only detected when large enough to cause issues such as odours and corrosion

- Over-sized odour control and treatment equipment, to deal with the volumetric expansion of the H₂S whilst gaseous

- Evolving H₂S hotspots in the sewer retic

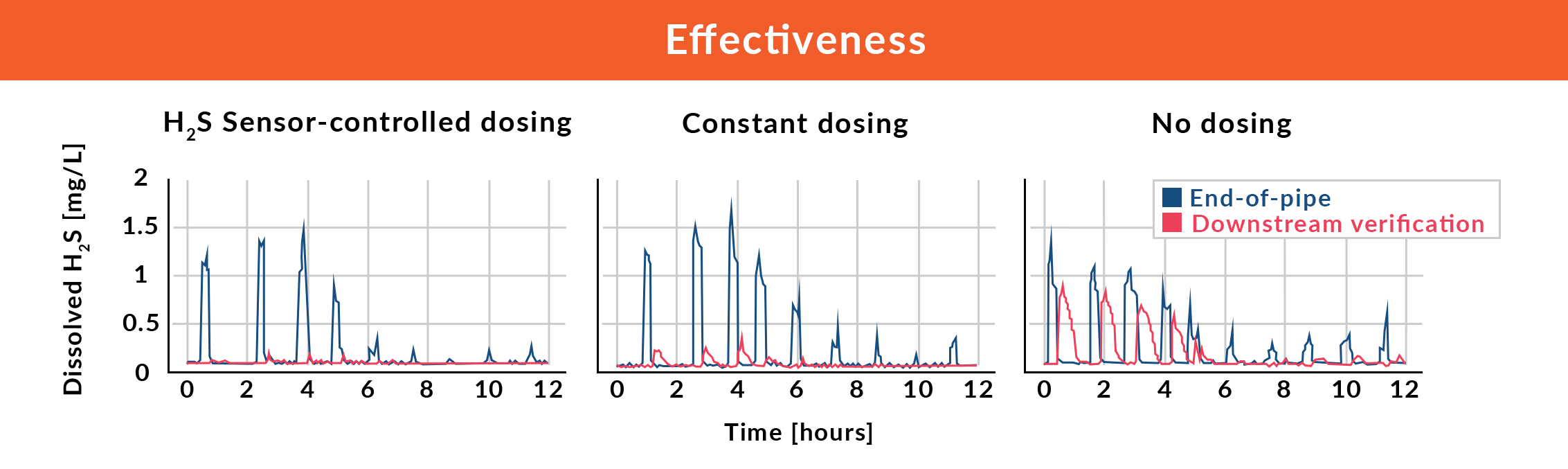

- Chemicals used for control measures such as dosing are either underdosed or overdosed

The solution: Sulfilogger's liquid phase H₂S logging

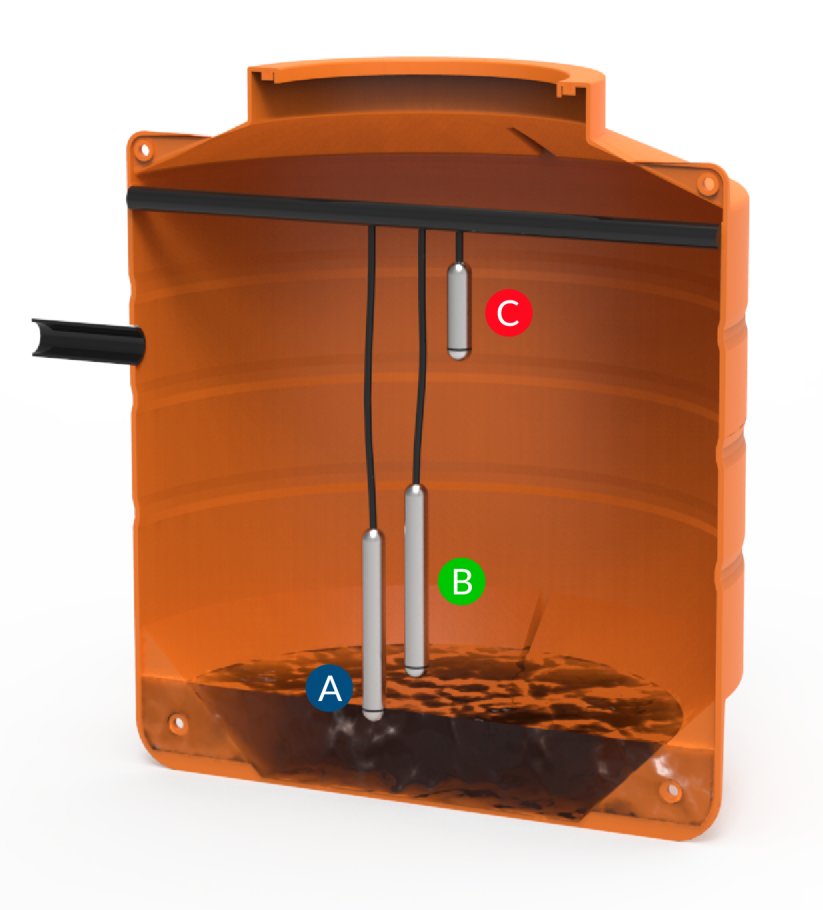

The SulfiLogger™ sensor continuously measures H₂S directly in wastewater, air, and inline in process gasses. The sensor provides reliable insights that empowers Asset Managers and Operators to adopt a data-driven and proactive approach to odour and corrosion control in Wastewater, Biogas, and Oil & Gas industries.

FEATURES

- Real-time sensor technology for H₂S & other liquid gas phase odour compounds including dimethyl sulphide, methyl mercaptans, and ethyl mercaptans

- Wireless connectivity for remote data logging

- Robust design for corrosive environments

- User-friendly interface

- Scalable to meet your needs

- Ex/ATEX versions for class 1, Zone 0, 1, 2

- Ability to locally calibrate instrument on site

BENEFITS

- Realise measurable outcomes by saving on operational cost

- Reliable monitoring unaffected by external factors: uninterrupted measurements

- Complete and dynamic overview of H₂S challenge

- Facilitating the use of data-based algorithms for monitoring and control

- Return asset life closer to the design life

- Enhanced safety to pick up on hazardous gases early, protecting your personnel and the environment

- Regulatory compliance – aids in meeting industry regulations and environmental standards

- Realise operation efficiencies, using data to better plan proactively with preventative maintenance

Hitting the issue at the biochemistry:

Take back control & reduce chemical use by 50%

Key Advantages

Durability

- Corrosion Free (LLDPE) collection chamber

- Compatible with acid sulphate soils

- Stainless steel guide rails and chain hoist

Credibility

- Australian owned manufacturing: 50 years experience

- Supporting buoyancy calcs and anchorage guidelines for site installation purposes

- Accreditations & Relevant Standards

Customisation

- Sized for your duty and control needs

- Class rate lids

- Configurable tank setups (max. depth 5m)

- Local and remote SMS alarms

Practicality

- Compact ‘Plug & Play’ control cabinet IP65

- Full automation control (inclusive of level control instrumentation)

- Internal or external isolation and check valve setup

- Expandable extra emergency storage (via storage logs)